Filter Casing

Airclean manufacture air filter housings, frames and casings, for all styles of air filters including panels, activated carbon filters and HEPA filters. Housings are available for duct mounted systems, front withdrawal within air handling units or ventilation voids, and terminal style housings for mounting within ceilings.

Using CNC our fabrication and sheet metal team produce high quality housings for all applications.

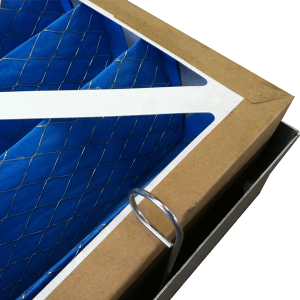

Front Withdrawal Frames are suitable to hold an individual bag or panel type air filter, or a combination of a 47mm Panel and Bag Filter. These frames allow filters to be removed from behind the frame, or from in front in a reverse airflow situation.

Multiple frames can be fixed together in unlimited formations to provide a filter bank of any size to suit any desired airflow.

Front withdrawal frame setups are commonly used where large airflows pass thorough large voids, or where a good filter seal is needed to prevent any bypass in ductwork systems or in air handling units.

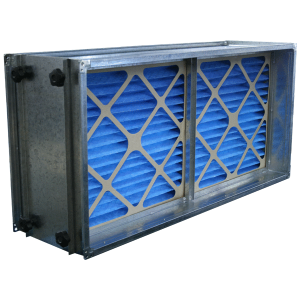

Side Access Filter Casings can be used to house, either panel or bag style air filters. Using the MEZ flange system, this housing can be easily installed into a rectangular duct run, or in to a spiral duct by adding transformations.

Filter casings in this style, can be made in any reasonable size to accommodate a range of airflows. Cases for multiple filter installations can be manufactured.

Duct Mounted Filter Boxes are commonly used for low efficiency filtration applications in spiral wound duct work. Low grade panel or bag filters can offer protection to inline system components such as fans, coils and heater from dust particles. Various airflows can be supported in all of the standard wound spiral dimensions.

Side Withdrawal Filter Housings are designed with efficient filtration in mind, ensuring that the filters selected can achieve their potential in critical applications.

This style of housing is often used to house HEPA filters in sensitive environments such as laboratories and hospitals. In addition it can be offered to house Carbon filters for odour control in restaurants, or the removal of harmful gases in medical or industrial applications.

The Terminal Housing is the traditional method for fitting HEPA Filters into a duct-work system ensuring high quality clean air is supplied directly to the clean room or equipment where it is required.

The Terminal Housing allows air from the HEPA filter fitted within the housing, to have a minimal time period in which to collect contamination from the surrounding parts of the housing.

The HEPA Filter is changed from within the cleanroom, by removing the 4 way grille and the clamping bolts/removable clips, releasing the HEPA filter from its knife edge or liquid seal, sealing face.

In some applications changing the filter from within the cleanroom could compromise its cleanliness, and for this application a rear or side withdrawal system has been devised.

This Low Level HEPA Extract Housing offers a solution where contaminated air must be extracted to atmosphere, and needs to be deemed safe for discharge.

This system has been adopted for use in Isolation Wards, testing laboratories, Pharmaceutical Manufacturing facilities, to ensure the safety of the discharge, and facilitate the diagonal airflow in a room i.e. ceiling supply to low level extract.

Its high-quality white finish allows for the unit to be in keeping with a medical environment and cleanable.

Lead Time

MEZ Flanged Side Access Casings and Duct Mounted Filter Boxes – Approx 7 to 10 days

All Welded Housings – Approx 2 to 3 weeks