- Technical Bulletin – HEPA Air Pressurisation Unit (APU) Set-ups March 18, 2024

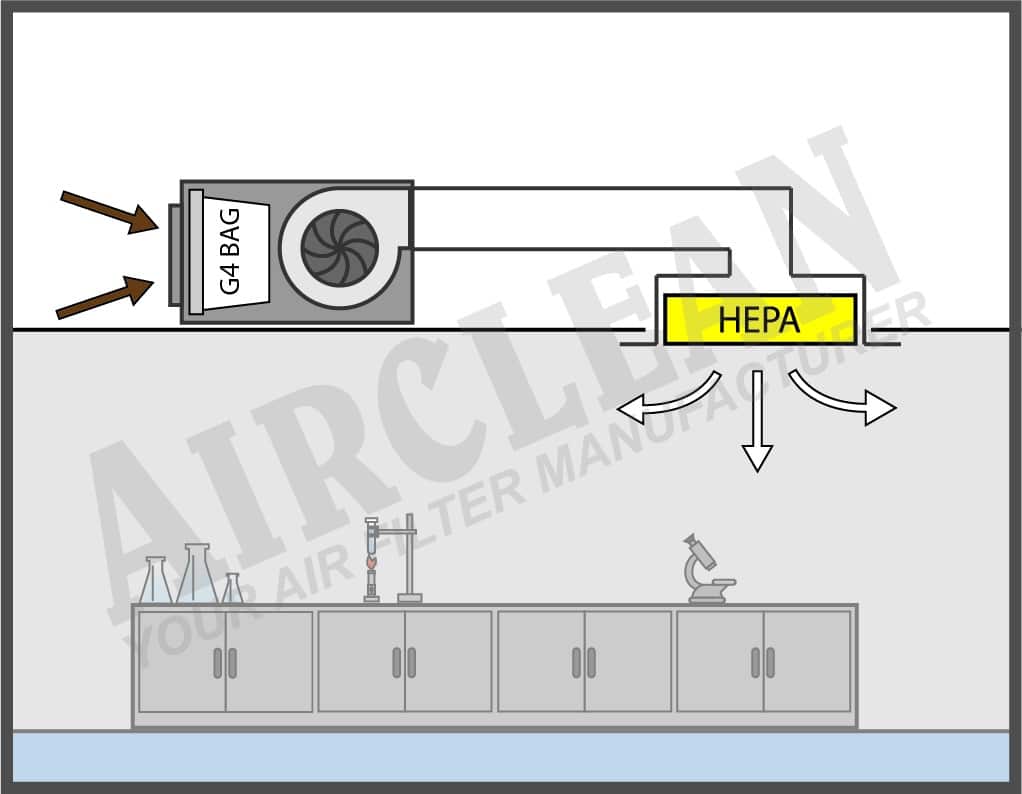

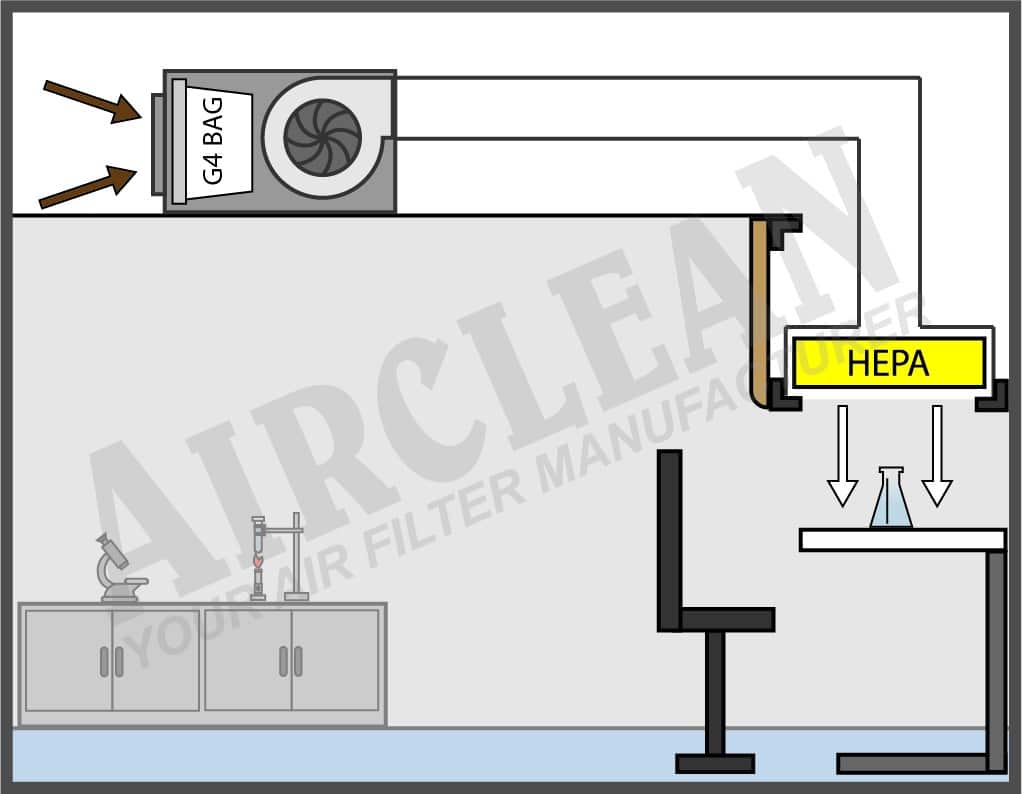

Typical Air Pressurisation Unit Set-up

- Positive pressure 100% supply air.

- Prefilter + H14 HEPA Cassette.

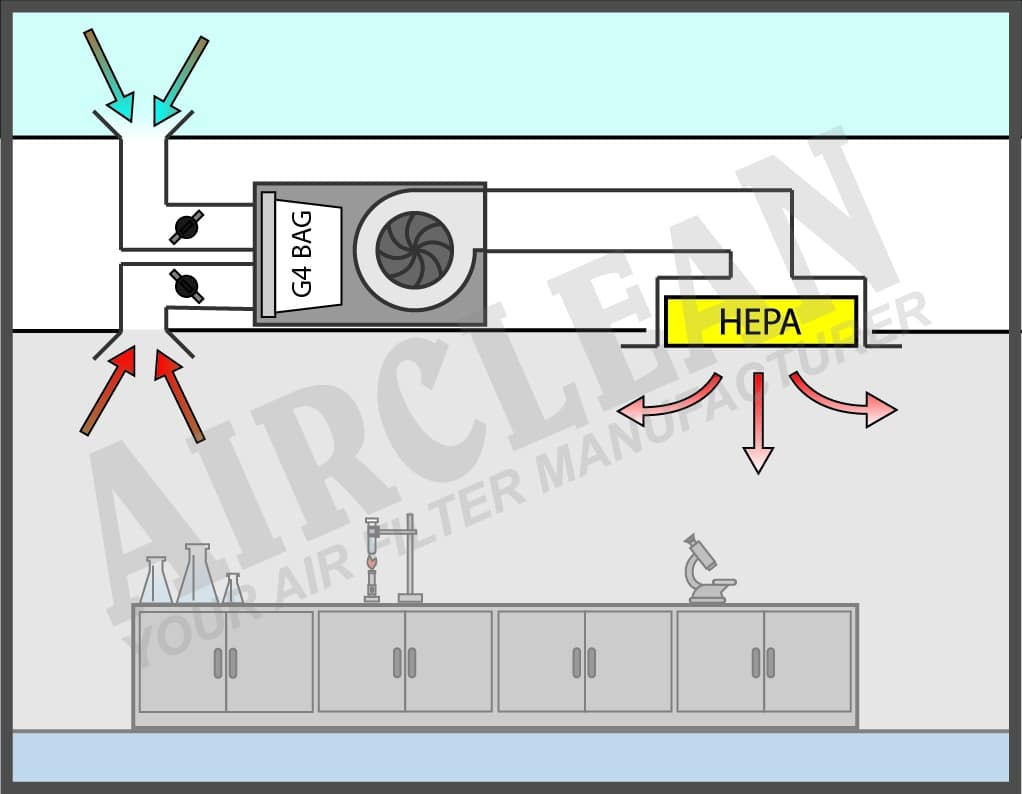

Hybrid Heat Recovery Recirculation Air Pressurisation Unit Set-up

- Recirculation solution with fresh air addition.

- Dampeners allow for balancing.

- Additional inlet spigots on request.

- Dampers & additional ducting supplied by others.

Laminar Flow Bench Air Pressurisation Unit Set-up

- Using APU to attain laminar flow with positive pressure clean room.

- Activated Carbon Filters – Adsorption not Absorption March 5, 2024

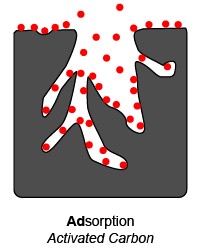

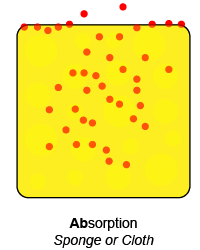

When we talk about how an Activated Carbon Filter works we use the word “Adsorption” to describe the process of molecules being removed from the air stream. However, we often hear the more common word “Absorption” incorrectly used.

What is the difference between Adsorption and Absorption?

“Adsorption“

Is a process where atoms, ions or molecules from a gas, liquid or solid, stick or adhere to the surface of a material. eg. Activated Carbon Filter.

“Absorption“

Is a process where atoms, ions or molecules are drawn into or soak into a material. e.g. sponges or paper towels, taking on water.

Activated Carbon Filters

Airclean offers activated carbon filters in various styles, primarily as bonded panel filters. Multiple panels can be combined to form a carbon discarb filter cell for high carbon loading and increased airflow support. For odour control at lower levels, activated carbon impregnated media are available in both traditional bag filters and rigid bag filters.

- Pop-up Christmas Tree Instructions – Airclean Gift Christmas 2023 December 6, 2023

Season’s greetings!

As the holiday season unfolds, we’re excited to add a touch of joy to your celebrations. To kick off the festivities, we’re delighted to present you with a small gift—a pop-up Christmas tree.

Made from our top-quality Airclean Moisture Resistant (AMR) Cardboard, this tree is a testament to the versatility of our materials. In fact, our AMR Cardboard is a key component in many of our panel filters, offering exceptional protection against high moisture environments.

Now, it’s time for the fun part! We invite you to unleash your creativity and transform this blank canvas into a festive masterpiece. Decorate your pop-up Christmas Tree with the included bauble stickers or add your own flair.

We’d love to see the magic you create! Share pictures of your decorated pop-up Christmas tree with us by emailing them to sales@airclean.co.uk.

Merry Christmas and Happy Decorating!Warm regards,

The Airclean Team - Airclean Annual Christmas Shutdown 2023 December 1, 2023

Airclean Christmas and New Year Shutdown

Close: 5:00pm Thursday 21st December 2023

Open: 8:00am Tuesday 2nd January 2024Where you have filters that you require before the Christmas break please get your orders to us as soon as possible.

Speak to the Sales Team if you have any specific requirements.

Please contact us on:

Tel: 01622 832777 or Email: sales@airclean.co.uk. - Don’t be spooked by non-standard air filters October 31, 2023

Having a “Nightmare” getting your hands on Non-Standard air filters!

Do Not “Fear”

Airclean have all the “Trick and Treats” and make Non Standard Air Filters to order!

For a “Spook-tacular” Halloween!

Call Our Sales Team with your air filter needs.

Airblog

August 3, 2020