Activated Carbon Panel Filters – Odour Control

– Coconut Shell Based Activated Carbon

– Free Carbon Testing Service (CTC Testing)

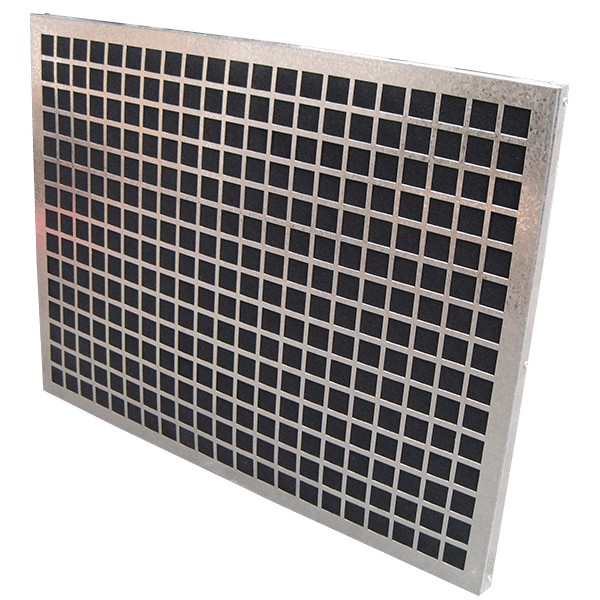

– Bonded Activated Carbon Panels

– Galvanised Steel frames

– Loose Fill Activated Carbon Panels now available

Applications

Activated Carbon Panel Filters are normally supplied fitted with an aluminium frame and can be made to any reasonable size to match existing panels of all makes.

The depth of the Bonded Carbon Panel Filter is restricted by our own imposed limits of not less than 10mm and not greater than 60mm Actual depth.

Capacities shown for Activated Carbon Panels & Activated Carbon Discarb Cells are based on a dwell time of 0.1 seconds, which is the normally accepted minimum for most applications.

Description

For heavier odours i.e. Indian or Thai cooking odours, a contact time of 0.3 seconds with the Carbon Filter is recommended to ensure effective odour control, which will effectively reduce the Face Velocity and rating to one third.

Where hot air is being filtered (e.g. extract from cooker hoods) the Activated Carbon Panels or discarb cells should be positioned as far from the heat source as possible, so as not to compromise effective odour removal.

Air stream temperatures in excess of 40°C should not be exceeded. If temperatures in excess of this figure are anticipated, the air temperature should be reduced by means of a fresh air bleed or a cooling coil.

Humidity levels must be maintained below 80%RH for air passing through the Activated Carbon Panel – this can be achieved by mixing with dry air or conditioning the airstream.

Pre-filters should be fitted in the ventilation system to protect the Activated Carbon Filters, to protect the Carbon Filters and ensure a good life for the filter. We do not consider a glass panel to be suitable and recommend a filter having a minimum grade of F5 to EN779, such as a general purpose multi pocket filter.

Some cooking operations give off large amounts of smoke, which is extremely detrimental if allowed to reach the Carbon Filters( smoke is a particulate). (See HEPA Filters, or Electrostatic Precipitators for smoke control)

Carbon Grading

Grade 20 Activated Carbon Filters are rated 30% on their ability to adsorb carbon tetrachloride (CTC) in testing; and have a typical surface area per weight of between 700-800 m2/g by the BET N2 method (the area being a measure of the area of the walls of the cavern like structure of the activated carbon): Bulk density is between 0.55 – 0.59 g/cc

Grade 50 Activated Carbon Filters are rated 55% on their ability to adsorb carbon tetrachloride (CTC) in testing; have a typical surface area per weight of between 1100-1200 m2/g by the BET N2 method (the area being a measure of the area of the walls of the cavern like structure of the activated carbon): Bulk density is between 0.49 – 0.53 g/cc

CLICK HERE FOR FURTHER ODOUR CONTROL SOLUTIONS FOR KITCHEN SYSTEMS

Activated Carbon Panel Filters Selection Tables

For Non Standard Sizes please contact on 01622 832777 or fill in the contact form below: