Ozone Odour Control System

- Ozone Injection system for the control of nuisance odours from kitchen extract systems

- Can operate on airflows from 0.8m3/s to 8m3/s

- 1.5 to 2 second dwell time required in ductwork system

- Simple to install, and can be retrofitted

- Optional monitor to control ozone discharge levels to within safe limits.

- Ability to add additional ozone injectors in the future.

- Low maintenance

Applications

The Ozone Odour Control System can neutralise nuisance odours which emit from cooking in commercial kitchen extract systems with airflows ranging from 0.8m3/s to 8m3/s.

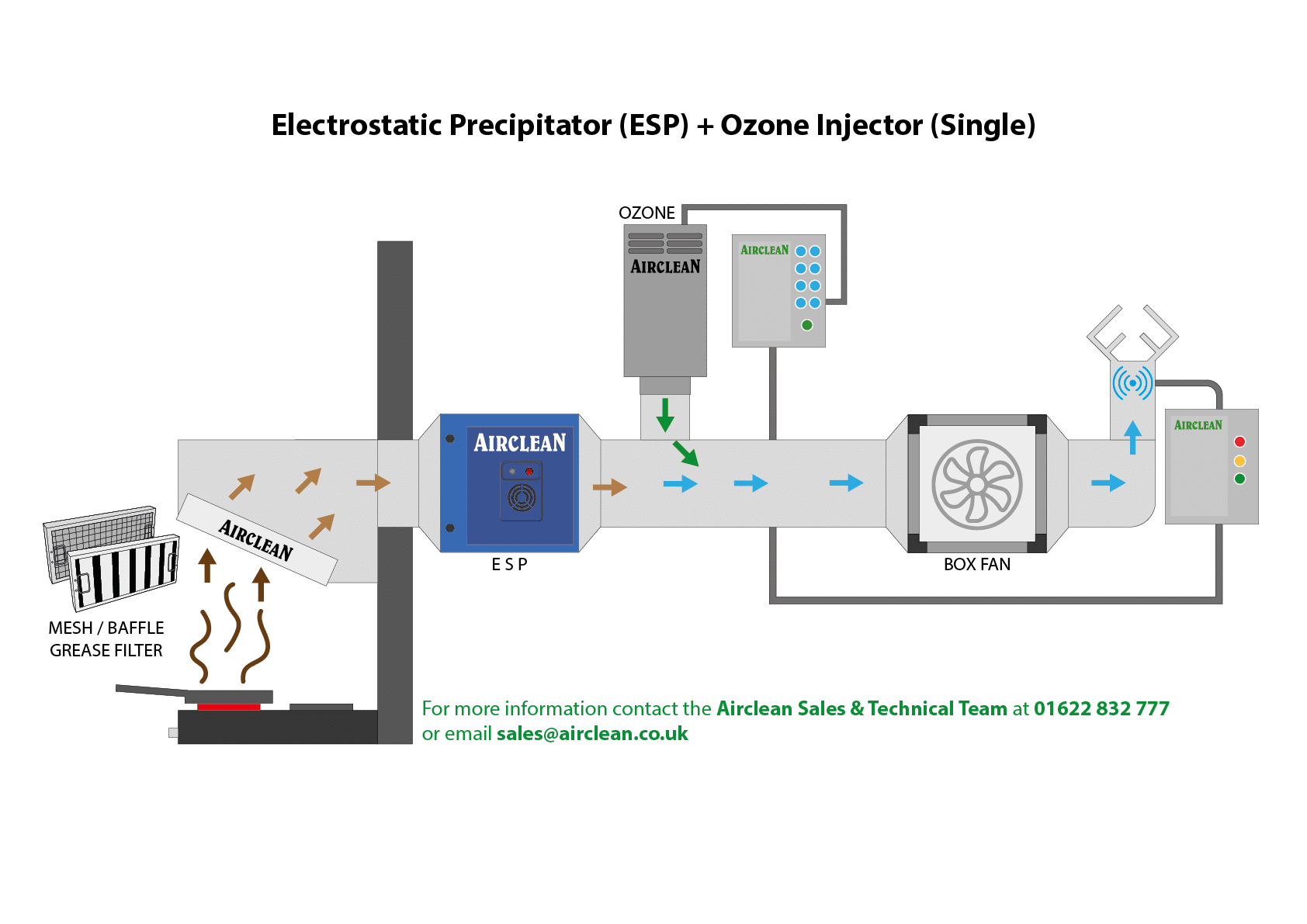

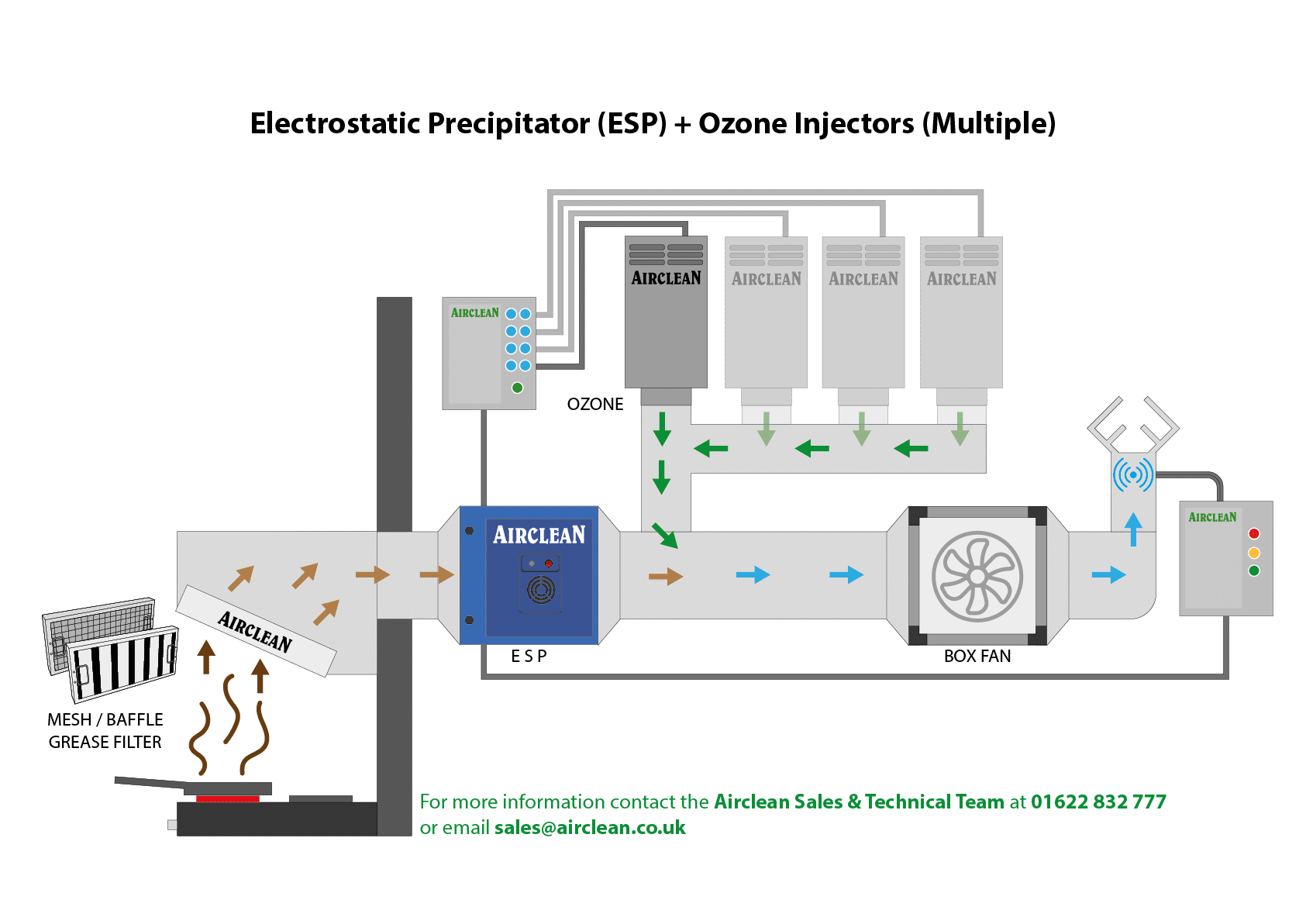

A number of Ozone Injectors will be required depending on the airflow volume, contact time, and style of cooking from the kitchen. Ozone injectors should be positioned alongside the canopy plenum or kitchen extract duct run on the negative air pressure side, at the earliest possible point to ensure the maximum contact time (minimum of 1.5 seconds from point of injection).

An Ozone Injector Control Box should be located next to the injectors to indicate the correct operation of each injector and Control Ozone discharge when used in conjunction with a Controlled Ozone Sensor Module.

The injectors will generate ozone when a negative pressure in the duct is detected by the control Box.

Controlled Ozone Monitor

Whilst ozone is a useful tool to reduce odours, it is hazardous to health in excess concentration / quantity, and unsafe discharge must be considered with each installation.

An optional Controlled Ozone Monitoring Module is available which uses an on board ozone sensor to detect the ozone level at the point of discharge. The Controlled Ozone Monitoring Module feeds back excess readings to the Injector Control Box, and will reduce ozone input, until the discharge reaches a safe ozone discharge level.

Injectors should be interlocked with the kitchen extract ventilation system.

Description

Ozone Injectors and Control Box

The Ozone Odour Control System compromises of a series of Ozone Injectors which are linked to a Control Box. The Ozone Injector Control Box can operate between one to four injectors, with each injector capable of injecting up to 20 grams of ozone in 10 gram increments. The Ozone Injector Control Box contains a series of lights which indicate the ozone level being injected.

Ozone Injectors are to be mounted on the negative pressure side of the kitchen extract (typically before the fan) allowing for ozone to be injected into the air stream by the natural draw of the system pressure. Negative pressure is detected and monitored from a pressure tube between the Control Box and the kitchen extract duct work.

| Component | Dimensions | Details |

|---|---|---|

| Ozone Injector | 150 x 150 x 330 mm | Stainless Steel Case 2x 10 Gram per Hour Gaseous Ozone Reactors 1x Power on Indicator Lamp 1x Ozone Production Lamp Single Phase, 240V |

| Ozone Injector Control Panel

(1 supplied with every system) |

155 x 200 x 95 mm | LED Indicator Lamps Electronic Air Pressure Sensor 4x 5 pin Monitor Output Sockets 1x 5 Pin BMS Output Socket 1x 5 Pin Data Logger Output Socket |

Optional Ozone Monitor for Controlled Ozone

An optional Ozone monitor can be added to the end of the duct just before the discharge point to measure and control ozone output levels.

The Ozone Monitor and Injector Control Box are linked together by a supplied communication cable. The Ozone Injector Control Box uses sensor readings from the Ozone Monitor to then automatically lower or raise the ozone injectors output in 10 gram intervals until the Ozone monitor registers the correct ozone levels.

| Component | Dimensions | Details |

|---|---|---|

| Ozone Monitor | 150 x 150 x 330 mm | 1x Power on Indicator Lamp 1x Monitoring Indicator Lamp 1x Dwell Indicator Lamp Includes long fly lead for connection back to Ozone Injector Control Panel (Length TBA on Order) |

| Part Number | Air Volume | Number of Injectors | Required Dwell Time (Seconds) | Ozone Delivery |

|---|---|---|---|---|

| 1913221 | 1 – 2 m3/s | 1 Injector* | 1.5 – 2s | 10 – 20g |

| 1913222 | 2 – 4 m3/s | 2 Injector* | 1.5 – 2s | 30 – 40g |

| 1913223 | 4 – 6 m3/s | 3 Injector* | 1.5 – 2s | 50 – 60g |

| 1913224 | 6 – 8 m3/s | 4 Injector* | 1.5 – 2s | 70 – 80g |

| *1x Injector Control Box is included and required to control up to 4 No. Injectors

A minimum contact / dwell time from the point of injection must be a minimum of 1.5 seconds for effective odour control. |

||||

| Part Number | Description | Size |

|---|---|---|

| 1913229 | Controlled Ozone Monitor (Optional) | 155 x 200 x 95 mm |

Baffle Grease Filter

Baffle Grease Filter Carbon Filter

Carbon Filter Electrostatic Precipitator

Electrostatic Precipitator Kitchavent 2000 / 3000 / 4000

Kitchavent 2000 / 3000 / 4000 Kitchen Extract AHU

Kitchen Extract AHU Controlled Ozone Injection System

Controlled Ozone Injection System Airclean Odour Neutraliser

Airclean Odour Neutraliser